In today’s world of personalized products and custom-made creations, CO2 laser cutters are becoming an essential tool for hobbyists, designers, and businesses. They offer a blend of precision, efficiency, and versatility that can transform a wide range of materials into intricate designs and shapes. When it comes to making custom toys and games, CO2 laser cutters stand out for their ability to bring complex ideas to life with incredible detail and accuracy. This article explores how CO2 laser cutters can be a game-changer in creating custom toys and games, opening up endless possibilities for creativity and production.

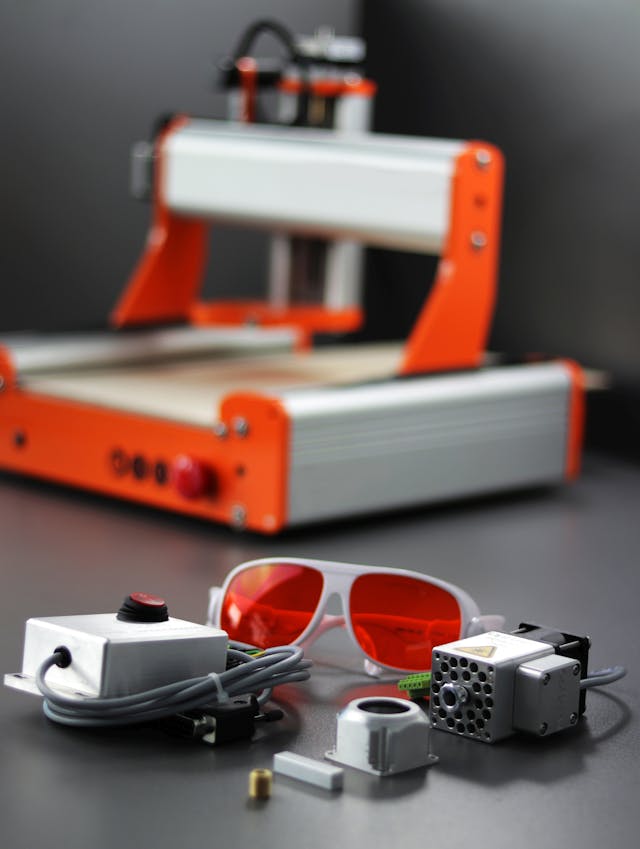

The Power of CO2 Laser Cutters

A CO2 laser cutter operates by focusing a beam of laser light onto a material, either cutting through it or engraving its surface. CO2 lasers are particularly well-suited for non-metallic materials such as wood, acrylic, plastics, leather, and fabrics, all of which are commonly used in toy and game design. These machines have gained popularity for their ability to produce precise cuts with smooth edges, making them ideal for intricate designs and detailed patterns.

What sets CO2 laser cutters apart is their level of precision, which allows users to create highly detailed parts and components for toys and games. Whether you’re making a wooden puzzle, a complex board game, or custom figurines, the laser cutter can handle fine details that would be difficult to achieve by hand or with traditional cutting methods.

Materials and Flexibility

One of the key advantages of using CO2 laser cutters for toy and game creation is their compatibility with a wide variety of materials. For instance:

- Wood: Wooden toys are timeless, and laser cutting allows for highly detailed, durable wooden creations such as puzzles, blocks, and interactive games.

- Acrylic: This lightweight, shatter-resistant material is excellent for creating colorful, transparent pieces for board games, tokens, or action figures.

- Cardboard and Paper: For lightweight and inexpensive projects, laser cutting paper and cardboard can yield impressive results. These materials can be used to create prototypes or intricate game elements like dice, tokens, and game boards.

- Leather: Laser cutters can also handle leather, which is perfect for creating durable components for luxury or niche toys and games.

- Plastics: Many modern toys and games are made from various forms of plastic, and CO2 laser cutters can engrave or cut through plastic with ease, making them ideal for creating high-quality, custom game pieces.

Precision and Customization

The precision of a CO2 laser cutter is one of its most significant benefits. Modern CO2 laser cutters can achieve high-resolution cuts that are incredibly smooth and accurate. This precision is vital for creating custom toy and game pieces that fit together perfectly, especially in complex systems like interlocking puzzles or detailed game boards.

Customization is at the core of the toy and game industry today. Customers are looking for unique, one-of-a-kind items, and businesses or hobbyists can use laser cutters to meet these demands. The ability to upload custom designs into the machine allows for limitless customization options, whether it’s creating a personalized name puzzle for a child or designing a custom game board with intricate artwork. With software integration, the design process is simplified, and users can create custom items with ease, offering personalized products that resonate with consumers.

Rapid Prototyping and Iteration

Another significant advantage of CO2 laser cutters is their ability to facilitate rapid prototyping. In the toy and game design process, creating prototypes is essential for testing ideas and ensuring functionality. Traditional prototyping methods can be slow and costly, but with a CO2 laser cutter, designers can quickly iterate and refine their designs in a matter of hours rather than days or weeks.

For example, a game designer can create a prototype of a new board game with custom game pieces and a board layout. If changes are needed after playtesting, the designer can easily adjust the digital file and produce a new version quickly. This rapid prototyping capability speeds up the development process, allowing designers to experiment with new concepts and fine-tune their creations efficiently.

Safety and Efficiency

CO2 laser cutters are also known for being relatively safe and user-friendly. While they use high-powered lasers, the machines are typically enclosed in a protective casing, and many models feature safety mechanisms like automatic shut-offs. This makes them suitable for use in workshops, schools, or even at home, as long as proper safety precautions are followed.

In terms of efficiency, laser cutters are far superior to manual cutting tools or other machines like CNC routers. The laser operates quickly and can produce multiple copies of a design in a short period, making it ideal for small-scale production or creating multiples of the same toy or game element.

Encouraging Creativity and Innovation

One of the most exciting aspects of CO2 laser cutters is the way they foster creativity. For hobbyists, the ability to transform ideas into physical objects opens up a new world of possibilities. Whether it’s creating custom puzzles, toy cars, or detailed figurines, CO2 laser cutters give individuals the tools to turn their imagination into reality.

For businesses, CO2 laser cutters can be a valuable investment that enables them to offer highly personalized products. From custom game boards with unique engravings to limited-edition toys, businesses can use laser cutters to differentiate their products in a crowded market.

Additionally, the accessibility of CO2 laser cutters has grown in recent years. As more affordable models become available, small businesses and individual creators can now access the same level of precision and quality that was once reserved for large-scale manufacturers.

The Future of Custom Toys and Games

As technology continues to advance, CO2 laser cutters will play an increasingly important role in the toy and game industry. The ability to create custom, personalized products on-demand will continue to drive innovation, offering customers products that are not only unique but also tailored to their preferences. With the growing demand for sustainable, eco-friendly toys, the flexibility of laser cutters to work with materials like wood and recycled plastics will also become more critical.

In conclusion, CO2 laser cutters are revolutionizing the creation of custom toys and games by offering unparalleled precision, flexibility, and efficiency. Whether for hobbyists or businesses, these machines enable the production of highly detailed, personalized creations that bring imaginative ideas to life. As the technology continues to evolve, the possibilities for innovation in the world of custom toys and games are endless.

Add Your Comment